Electropolishing Applications in the Medical Field: Enhancing Safety and Performance Electropolishing is a precise electrochemical process essential for refining metal surfaces. By removing a thin layer of material, it achieves a smooth, clean, and corrosion-resistant finish. This technique is indispensable in the medical field, where the quality and biocompatibility of metal surfaces directly impact patient safety […]

Electropolishing Applications in the Medical Field: Enhancing Safety and Performance

Electropolishing is a precise electrochemical process essential for refining metal surfaces. By removing a thin layer of material, it achieves a smooth, clean, and corrosion-resistant finish. This technique is indispensable in the medical field, where the quality and biocompatibility of metal surfaces directly impact patient safety and device performance.

Key Benefits of Electropolishing for Medical Devices

- Surface Smoothness: Removes microscopic burrs and surface irregularities, creating a smooth, mirror-like finish crucial for medical devices that encounter human tissue.

- Corrosion Resistance: Enhances the corrosion resistance of metal parts, essential for implants and instruments exposed to bodily fluids.

- Biocompatibility: Reduces the likelihood of adverse reactions, making electropolished surfaces ideal for implants and other medical devices.

- Cleanliness: Achieves smooth, non-porous surfaces that are easier to sterilize, reducing infection risks.

Applications of Electropolishing in the Medical Field

- Dental Implants require precise and biocompatible surfaces to ensure successful integration with the jawbone and oral tissues.

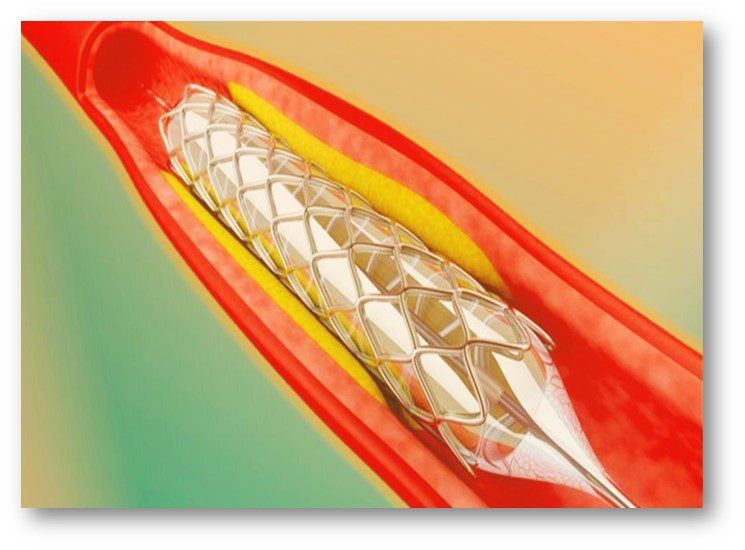

- Cardiovascular stents and other implantable devices used in heart surgeries need to be highly biocompatible, and corrosion-resistant to minimize the risk of thrombosis (blood clotting) and ensure effective function without causing adverse reactions in the bloodstream.

- Surgical Instruments must be sterile and free of contaminants. Electropolishing provides these instruments with ultra-smooth surfaces that are easy to clean and sterilize, thereby reducing the risk of infections and ensuring they remain sharp and effective during procedures.

- Diagnostic Equipment components that meet bodily fluids undergo a process to create smooth, polished surfaces. These surfaces prevent contamination and ensure accurate diagnostic results, which is crucial for equipment like endoscopes and biopsy tools.

- Orthodontic Devices such as braces and retainers, are in constant contact with the sensitive tissues of the mouth. Electropolishing these devices reduces the risk of irritation and improves patient comfort. Additionally, smooth surfaces are easier to clean, maintaining oral hygiene.

- Prosthetics: Limbs and other devices benefit from electropolishing by gaining enhanced surface properties that improve their functionality and aesthetic appeal. The process ensures that the metal components of prosthetics are smooth, durable, and resistant to corrosion, which is essential for long-term use.

- Orthopedic Implants: Hip and knee replacements benefit significantly from electropolishing, ensuring smooth, corrosion-resistant surfaces that reduce irritation and adverse reactions.

Conclusion

Electropolishing plays a crucial role in the medical and surgical industries, by enhancing the safety and performance of medical devices. Across orthopedic and dental implants, cardiovascular devices, surgical instruments, and diagnostic equipment, electropolishing improves functionality and reduces the risk of adverse reactions and infections.

Contact the Control team today to find out more about the benefits of electropolishing and its effectiveness for the broadest range of industries.